Charging guide: Charging from an electric outlet

The survey "Elbilisten 2020" shows that 27% of respondents still charge their electric vehicles via an ordinary household socket (schuko) when charging at home. There are various reasons why many people use this socket for daily charging of their electric vehicles. Everything from ignorance to advice from a car dealer. In addition, there are many who say on various forums that there is no danger associated with using the socket. We would like to point out that there are actually several risk factors related to charging the car via the socket that was installed in the garage or house many years ago.

Overload of electrical systems

Older electrical systems are usually not designed and built to handle the new equipment that is installed and connected today. Charging equipment for electric vehicles represents a new load in most electrical installations. Charging electric cars and plug-in hybrids draws a continuous high current and this will mean that any weaknesses in the electrical installation can be heated, especially connections. These are connections that the current must pass on the way from the fuse box to the socket, for example in junction boxes, light switches and other sockets. When these connections becomes hot, they weaken further and over time cause dangerous overheating and a risk of fire. By installing a dedicated charging point for the vehicle, this risk will be removed because a dedicated course is laid out for the charging point with its own protection. The power cable goes directly from the fuse box with protection to the charging point and the installation is sized to withstand the load.

No or reduced earth fault protection

Electric vehicles charging can create noise on the power grid which can affect earth fault protection. In the worst case, charging can result in the earth fault protection not working, both for the current course the vehicle is charging on, as well as other current courses in the electrical system. Although this does not happen often, the consequences can be fatal if it were to happen. More about how this happens can be found here. By installing a charging station or a dedicated charging point according to the regulations, this will include the right type of earth fault protection for the charging point, and other earth fault protection will be connected so that they are not affected by the charging vehicle.

Overloading the socket / household socket

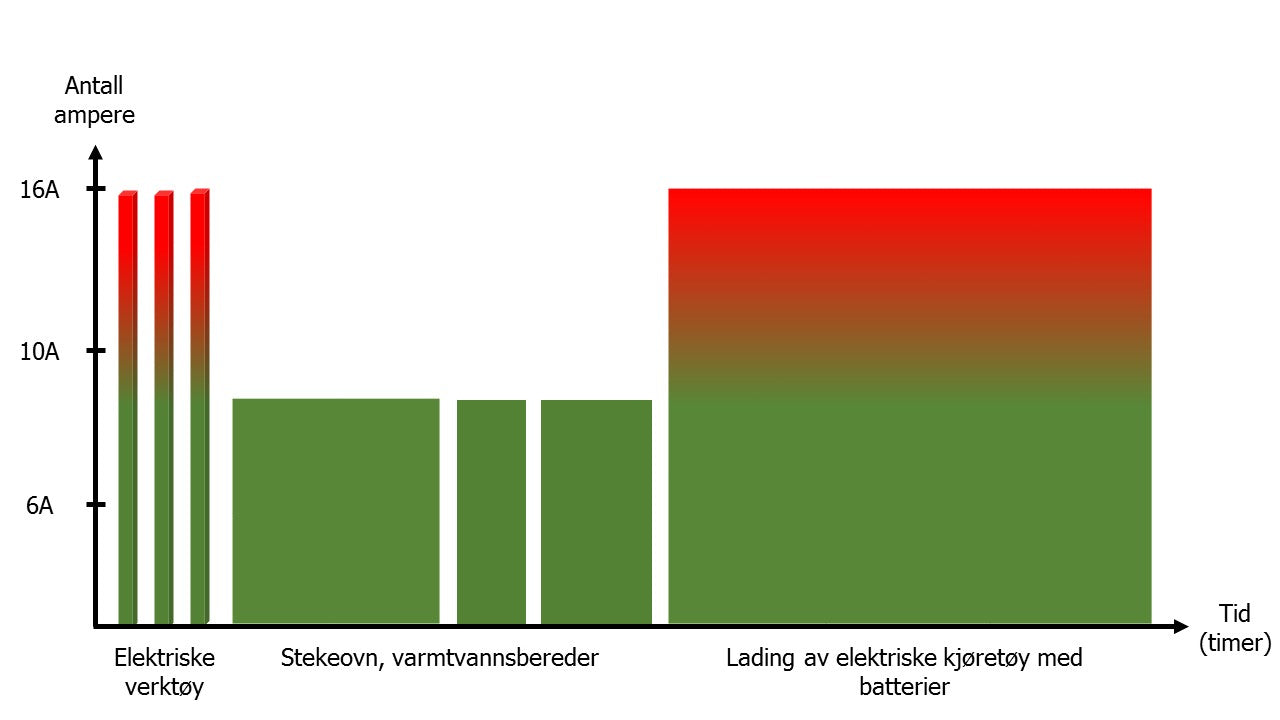

A household socket has been developed and dimensioned for easy connection of small loads such as lamps, kitchen equipment, electrical tools and the like. These are current chargers that normally draw upwards of 6-10 amps. It can withstand higher loads such as powerful hand tools for short periods. Daily charging of electric vehicles represents a continuous load over a long period of time (depending on battery size) that is at the limit of what a household socket can withstand. If the current is so great over time that it generates heat, this heat generation can in turn weaken the socket's springs so that the contact weakens and makes contact between conductors worse. This, in combination with high amperage, results in further heating with the risk of fire in the socket as the ultimate consequence. Below we have illustrated the various loads a normal socket will normally be exposed to.

Incorrect termination of charging

When charging via a household socket, there are no safety mechanisms to ensure that charging is terminated correctly. If the plug is pulled out of the household socket while charging, an electric arc may occur which damages the socket and, if repeated, the risk of overheating will increase significantly. A charging station will ensure that the charging current is interrupted in a safe way. This happens by locking the charging cable to the car and charging station and charging must be terminated before the charging cable is released. If the locking mechanism does not work, the charging station will sense that the charging cable is being pulled out and interrupt the current in a controlled manner before an arc occurs in the contacts.

Although it is usually fine to charge via the socket, it is desirable to keep the risk as low as possible when charging. If you still have to use an old power supply with a socket, you can still reduce the risk yourself by ensuring that the socket is in good condition, as well as checking regularly for heat conduction in the plug and in the socket.

Special plugs and contacts

For example, the stove in your kitchen has a stove plug and socket because it uses a lot of electricity during use, but it is rarely used for more than one hour at a time and the effect is not as high over time. Electric vehicles are charged for several hours at a time, and with a higher output than the stove. Thus, charging with a new and dedicated charging point/charging station becomes safer, faster and allows you to charge the car all night without worries.

Guidance on charging equipment for electric vehicles

The Directorate for Social Security and Preparedness (DSB) has, in collaboration with the Norwegian Electrotechnical Committee (NEK), the Electric Vehicle Association and NELFO, developed a guide to the installation of charging equipment for electric vehicles. Their guidance (version 4 - July 2017) recommends a maximum continuous charging current of 8-10A from the household socket. Based on this, all new current courses with the household socket dedicated to charging electric vehicles are secured with a maximum of 10A.

Use of existing contacts

In permanent parking spaces for charging electric cars, safety against overloading and earth faults must be ensured. If an existing course with a normal contact is to be used for regular charging, this will be considered a change of use according to §16 of the regulation on low-voltage electrical installations which requires that the installation "must be suitable for intended use". The background is that charging an electric car will involve a significant change in the load pattern and type of load. Although a normal socket can be connected with 16A, it is not designed for this high load over time. DSB often experiences overheating and melting damage during inspections. Such damage is a major risk of fire. In addition, the charging system in the electric car will mask a normal earth fault switch which will then not work in the event of an earth fault. Life-threatening situations can then arise. Therefore, an earth fault circuit breaker type B must be installed which is not disturbed by the noise from the charging system.

This means that the course must be upgraded to the current regulations in the event of a change of use, i.e. earth-fault circuit breaker type B, as well as a maximum 10 A fuse for normal contact (current limitation does not apply to CEE/industrial contact contact). It is also important to check whether the facility can actually withstand the load in question over time. Contact an electricity company to check the condition of the system and get advice on any measures.

Alternative to the socket

An alternative to the standard socket is a blue or red CEE industrial socket (round pin). These have been developed to handle continuously higher amperages over time and will be more suitable for use in charging electric vehicles.

Industrial connectors are far more robust and have been developed to handle higher amounts of current over time. They are available in both 1-phase (3-pins) and 3-phase (4- and 5-pins) and are found in many industrial areas such as e.g. petrol stations. The blue CEE variants in particular have become particularly common in caravan parks and marinas throughout Europe. The color of the plug refers to the regional electrical power distribution with: yellow (110/120V), blue (230/240V) and red (400V). Today's electric cars handle alternating current (AC) 16A and 32A, both 230V and 400V. As a result, many people install these connectors as they are safer to use for electric car charging.

It is mainly the blue and red industrial connectors that you will find available. The blue industrial connector is available in two different versions:

1) 3-pin, 1-phase 230V (16A/3.7kW) and (32A/7.4kW)

2) 4-pin, 3-phase 230V (16A/6.3kW) and (32A/12.7kW)

The red industrial connectors are mainly also available in two variants:

1) Small 5-pin, 3-phase 400V - up to 11kW (16A)

2) Large 5-pin, 3-phase 400V - up to 22kW (32A)

Note that there is a difference between the sizes of industrial connectors and plugs/plugs of 16A and 32A. For example, a 16A plug will not fit into a 32A socket, and vice versa.

FedEx delivery in the EU

FedEx delivery in the EU